- Hydraulic Shearing Machine液压剪板机

- QC12K NC, CNC Hydraulic Swing Beam Shearing machine 液压摆式剪板机

- QC11K NC, CNC Hydraulic Guillotine Shearing Machine液压闸式剪板机

- QF28Y Hydraulic Nothing Machine液压切角机

- Circle shearing cutting machine

- Bending Machines(Press Brake)液压折

- WC67K NC Hydraulic Press Brake NC控制液压折弯机

- WE67K CNC Hydraulic Press Brake 数控折弯机

- 2xWE67K Tandem CNC Press Brake双机联动数控折弯机

- WS Manual Pan Brakes手动折边机

- Rolling Machine卷板机

- W11 3 Rollers Mechanical Rolling Machine 三辊机械卷板机

- W11S 3 rollers Hydraulic Rolling Machine 三辊液压卷板机

- W12 4 rollers Hydraulic Rolling Machine 四辊液压(数控)卷板机

- W11F 3 Rollers Mechanical Rolling Machine三辊非对称机械卷板机

- Section Rolling/ Bending Machine 型材弯曲机

- cnc cutting machine

- Press and Stamp 压力机

- Punching machine 冲床

- Mechanical Shearing Machine机械剪板机

- Other Machines

Contact us

- ADD: No.106, Huanghai Boulevard, Hai’an Town, Hai’an County, Nantong, Jiangsu

- TEL: +86 13862701269

- FAX: +86-0513-87961814

- E-mail: ntwoke@yahoo.com

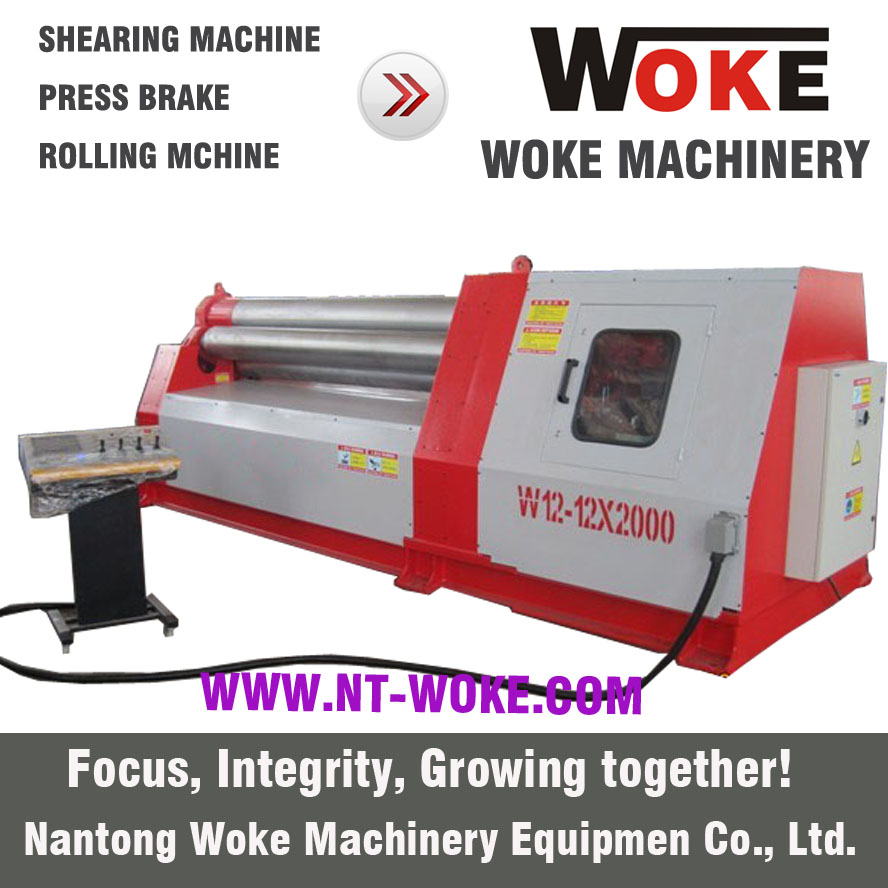

W12 Four rollers Hydraulic Plate Rolling Machine

- rolling machine

- cnc rolling machine

- W11S Three rollers Hydraulic Plate Rolling Machine

- W12 Four rollers Hydraulic Plate Rolling Machine

- Product description: High positioning Long service life Competitive price W12 Four rollers Hydraulic Plate Rolling Machine

Product introduction

W12 Four rollers Hydraulic Plate Rolling Machine

Rolling Machine Performance

The machine is four roller plate bending machine, its structure shown as drawing 1, upper roller as initiative roller, down roller and side rollers as driven rollers; upper roller is fixed, down roller does up and down movement; upper roller is Hydraulic initiative, while down roller and side rollers are driven by friction from plate and rollers. Down roller and side rollers are driven by hydraulic oil tank to do lifting movement. Upper roller’s ventro-bearing overturn and reset are also driven by hydraulic oil tank. Rollers’ beraing and oil tank are installed on left and right side of machine frame.

Left and right machine framework are the main parts of whole machine, which is totally steel welded, installed on the welded base, and all operations are finished on console.

Rolling Machine Parameters

Specification

Thickness

mm

Width

mm

Yield

strength

Mpa

Roll speed

m/min

Min roll

Diameter

mm

Diameter of

upper roller

mm

Diameter of

down roller

mm

Diameter of

side roller

mm

Motor

kw

W12-25×2000

25

2000

245

4

800

350

320

240

22

W12-20×2500

20

2500

245

4

640

350

320

240

30

W12-30×2000

30

2000

245

4

1000

400

360

240

37

W12-25×2500

25

2500

245

4

800

400

360

240

37

W12-35×2000

35

2000

245

4

1200

420

380

210

37

W12-30×2500

30

2500

245

4

1000

400

360

230

37

W12-40×2000

40

2000

245

4

1400

480

400

420

45

W12-45×2000

45

2000

245

4

1600

500

450

380

45

W12-35×2500

35

2500

245

4

1200

480

400

420

45

W12-40×2500

40

2500

245

4

1400

500

450

380

45

W12-45×2500

45

2500

245

4

1600

530

480

450

63

W12-35×3000

35

3000

245

4

1200

500

450

380

45

W12-45×3000

45

3000

245

4

1600

560

500

450

63

W1-25×2500

55

2500

245

4

2000

600

550

500

75

W12-55×3000

55

3000

245

4

2000

620

560

500

75

W12-65×3000

65

3000

245

4

2400

670

600

550

110

Rolling Machine View

nt-woke@hotmail.com

nt-woke@hotmail.com lilyxu126

lilyxu126 cn1501598885

cn1501598885