- Hydraulic Shearing Machine液压剪板机

- QC12K NC, CNC Hydraulic Swing Beam Shearing machine 液压摆式剪板机

- QC11K NC, CNC Hydraulic Guillotine Shearing Machine液压闸式剪板机

- QF28Y Hydraulic Nothing Machine液压切角机

- Circle shearing cutting machine

- Bending Machines(Press Brake)液压折

- WC67K NC Hydraulic Press Brake NC控制液压折弯机

- WE67K CNC Hydraulic Press Brake 数控折弯机

- 2xWE67K Tandem CNC Press Brake双机联动数控折弯机

- WS Manual Pan Brakes手动折边机

- Rolling Machine卷板机

- W11 3 Rollers Mechanical Rolling Machine 三辊机械卷板机

- W11S 3 rollers Hydraulic Rolling Machine 三辊液压卷板机

- W12 4 rollers Hydraulic Rolling Machine 四辊液压(数控)卷板机

- W11F 3 Rollers Mechanical Rolling Machine三辊非对称机械卷板机

- Section Rolling/ Bending Machine 型材弯曲机

- cnc cutting machine

- Press and Stamp 压力机

- Punching machine 冲床

- Mechanical Shearing Machine机械剪板机

- Other Machines

Contact us

- ADD: No.106, Huanghai Boulevard, Hai’an Town, Hai’an County, Nantong, Jiangsu

- TEL: +86 13862701269

- FAX: +86-0513-87961814

- E-mail: ntwoke@yahoo.com

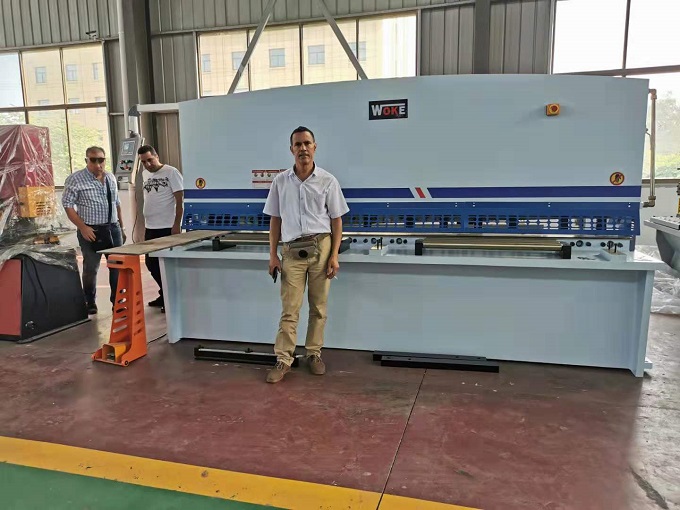

QC12K-4X2500/3200/4000 NC CNC Hydraulic Swing Beam Shearing Machine液压摆式剪板机

- shearing machine剪板机

- cnc shearing machine数控剪板机

- Hydraulic Swing Beam Shearing machine摆式剪板机

- cutting machine剪切机

- Product description: Precision positioning Long service life Competitive price cnc shearing machine

Product introduction

QC12Y QC12K NC ,CNC Hydraulic Swing Beam Shearing Machine Cutting Machine

NC, CNC 液压摆式剪板机

Shearing Machine Performance 剪板机性能

1. The frame and blade’s holder are both welded construction, vibration to eliminate stress with good precision;

钢板焊接结构,振动消除应力,精度高。

2. Hydraulic drive, return of knife beam is smooth and prompt by accumulator or nitrogen cylinder. With easy operation, reliable performance and nice appearance.

液压驱动,刀架在蓄能器或氮气缸作用下回程稳定快速。 操作简单,性能稳定,外形美观。

3. After welding, the frame is processed by CNC pentahedron at one time to ensure the rigidity and accuracy.

焊接后,机架数控五面体一次性整体加工,保证了较高精度和刚性。

4. Manual adjustable blade clearance. There is indicator for adjusting the blade clearance, easily operation.

刀片间隙手动调节,并有刻度盘显示,操作简单。

5. The forward and backward movement of back gauge is controlled by ESTUN or DELEM CNC control system.

后挡料前后运动由国内著名ESTUN或国际DELEM控制系统控制。

6. All major hydraulic and electrical elements are famous international brand.

主要液压和电气元件均采用国际著名品牌。

QC12Y-4 Series Shearing Machine Parameters QC12Y-4系列剪板机参数

|

Model 型号 |

Max. Shearing Thickness 最大剪切厚度 |

Max. Shearing Width 最大剪切宽度 |

Distance Between Uprights 立柱间距 |

Working Table Height 工作台高度 |

Strokes 行程次数 |

Back Gauge Stroke 后挡料行程 |

Shearing Angle 剪切角 |

Throat Depth 喉口深度 |

Main Power 主电机 |

Dimensions 外形尺寸 |

|

mm |

mm |

mm |

mm |

Min-1 |

mm |

° |

mm |

kw |

mm(L×W×H) |

|

|

4×2000 |

4 |

2000 |

2150 |

740 |

20 |

20-550 |

1°30' |

100 |

4 |

2500×1600×1550 |

|

4×2500 |

4 |

2500 |

2700 |

740 |

18 |

20-550 |

1°30' |

100 |

4 |

3100×1600×1550 |

|

4×3200 |

4 |

3200 |

3410 |

800 |

14 |

20-550 |

1°30' |

150 |

4 |

3800×1700×1650 |

|

4×4000 |

4 |

4000 |

4220 |

800 |

10 |

20-550 |

1°30' |

150 |

5.5 |

4650×1900×1750 |

|

4×4500 |

4 |

4500 |

4720 |

800 |

8 |

20-550 |

1°30' |

150 |

5.5 |

5150×1900×1750 |

Shearing Machine View

nt-woke@hotmail.com

nt-woke@hotmail.com lilyxu126

lilyxu126 cn1501598885

cn1501598885